Product Overview

This page provides a detailed engineering and procurement reference for the 22256 CC/W33, intended for buyers verifying exact bearing specifications and functional interchangeability before ordering.

As a cornerstone of heavy industrial machinery, the 22256 CC/W33 Spherical Roller Bearing is specifically developed by ZQM Bearings to sustain continuous operation in high-stress environments. Primarily used in primary crushers, vibrating screens, and large-scale conveyor systems, this model is the engineering choice for procurement professionals seeking a reliable replacement that meets rigorous ISO standards for load distribution and fatigue resistance. Its dual-row symmetrical roller design allows for substantial radial capacity while simultaneously managing heavy axial forces, ensuring structural integrity in critical industrial machinery where downtime is not an option.

Design & Engineering Advantages

The 22256 CC/W33 is synthesized from premium vacuum-degassed GCr15SiMn bearing steel. This material selection is a calculated engineering decision to mitigate the risk of fatigue spalling by controlling the oxygen content and minimizing non-metallic inclusions. In high-load industrial bearings, steel purity directly correlates to the fatigue limit, and our controlled manufacturing processes ensure that the 22256 CC/W33 maintains superior Hertzian contact stress distribution across the rolling elements.

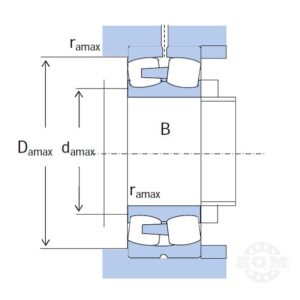

The internal geometry is optimized with a large (D – d) cross-sectional height, which provides the necessary radial depth to absorb heavy impact loads. Specifically, the ‘CC’ design features a reinforced pressed steel cage and symmetrical rollers. This configuration offers low friction and self-guiding characteristics, which are vital for thermal management during continuous high-speed operation. The steel cage ensures the bearing maintains its load-carrying capacity even during significant shaft deflection. Furthermore, the W33 lubrication groove and holes ensure a continuous supply of lubricant to the contact zones, maintaining a stable boundary lubrication layer and dimensional stability under varying thermal loads.

Key Features

- High-purity vacuum-degassed steel construction for enhanced fatigue resistance.

- Reinforced steel cage design for low-friction, self-guiding operation.

- Advanced internal geometry to compensate for shaft deflection and misalignment.

- Integrated W33 relubrication feature for continuous lubrication reliability.

- International standard conformity for seamless replacement in heavy industrial applications.

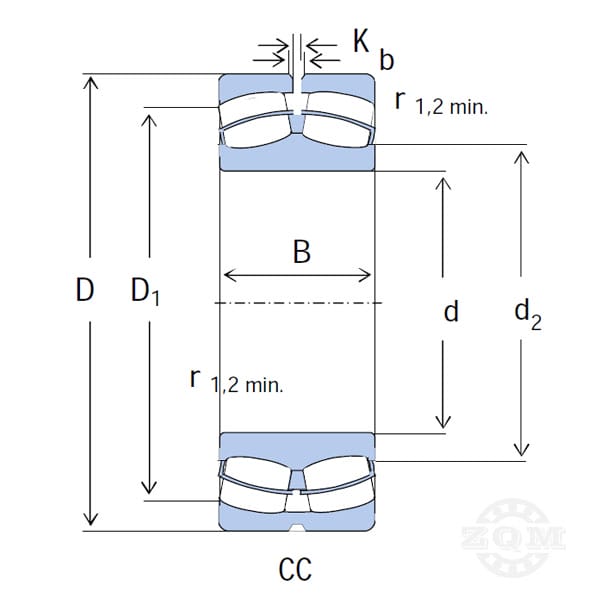

Boundary Dimensions

| Designation | 22256 CC/W33 |

| Bore diameter (d) | 280 mm |

| Outside diameter (D) | 500 mm |

| Width (B) | 130 mm |

Procurement Selection

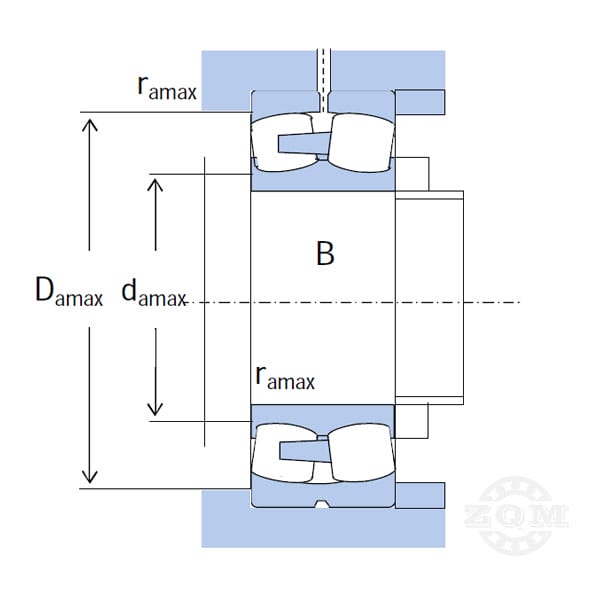

From a TCO (Total Cost of Ownership) perspective, the procurement of the 22256 CC/W33 represents a strategic decision to balance initial cost with long-term reliability. Engineering teams should prioritize this steel-cage model for applications where continuous rotation and heat management are more critical than extreme shock absorption. The functional interchangeability of the 22256 CC/W33 ensures that maintenance crews can perform field replacements without housing modifications. During procurement verification, engineering teams must cross-audit the d/D/B boundary dimensions against original equipment specifications to ensure precise installation fit and load path integrity, matching precisely the dynamic load ratings of Cr=2280 kN required for major industrial OEMs.

Cross-reference & Replacement

| ZQM Model | Reference Brand | Reference Model | Equivalence Basis |

|---|---|---|---|

| 22256 CC/W33 | SKF | 22256 CC/W33 | Dimensional conformity |

| 22256 CC/W33 | FAG | 22256-E1-XL | Installation interchangeability |

| 22256 CC/W33 | NSK | 22256EAE4 | Internal geometry compatibility |

ZQM Bearings ensures that our 22256 CC/W33 maintains dimensional consistency with leading international brands. This allows for seamless replacement in existing industrial housings without modifications to shaft or housing abutments. Always verify the calculation factors during engineering evaluation to ensure load ratings match the system requirements.

Typical Industrial Applications

- Primary Jaw and Cone Crushers

- Heavy-duty Mining Vibrating Screens

- Steel Rolling Mill Drives and Stand Supports

- Large Conveyor Head and Tail Pulleys

- Vertical Raw Mills in Cement Production

Service Life & Reliability

The reliability of the 22256 CC/W33 is grounded in advanced L10 life calculation logic. By maintaining a high material purity, ZQM effectively pushes the fatigue limit higher, ensuring the raceways resist subsurface-initiated spalling. The heat treatment stability of the rings prevents dimensional drift under thermal load, maintaining the internal clearance optimization necessary for friction torque reduction and lubrication reliability during continuous operation. This engineering approach ensures that the 22256 CC/W33 achieves its full theoretical fatigue life under combined radial and axial load paths.

Installation & Lubrication Notes

Successful operation depends on precise misalignment compensation. The 22256 CC/W33 can typically accommodate up to 2 degrees of misalignment; however, exceeding this limit results in edge loading and localized stress peaks. Relubrication via the W33 feature is essential for relubrication continuity, following the speed ratings of 630 r/min for grease and 800 r/min for oil. Incorrect installation or improper shaft fit can lead to thermal seizure or ring fracture, particularly in high-vibration mining environments.

Frequently Asked Questions

How does material purity influence the fatigue resistance of 22256 CC/W33?

Material purity is the primary determinant of the fatigue life cycle in the 22256 CC/W33. By using vacuum-degassed steel, ZQM minimizes non-metallic inclusions that act as stress concentration points under the contact subsurface. If inclusions are present, the constant Hertzian contact stress will trigger subsurface-initiated cracks, leading to premature spalling. High purity ensures that the 22256 CC/W33 maintains its dimensional stability and load-carrying capacity over the full service cycle.

Why choose a steel cage (CC) instead of a brass cage (CA) for 22256?

The CC design with its steel cage is generally preferred for applications emphasizing low friction and continuous, high-speed operation. The reinforced pressed steel cage is lighter and provides better self-guiding for the rollers, which is critical for maintaining thermal stability and reducing friction torque. While brass cages (CA) are superior for shock and vibration, the CC variant in the 22256 CC/W33 is the superior choice for high-speed conveyor pulleys and mill gearboxes.

What causes edge loading in spherical roller bearings and how to prevent it?

Edge loading occurs when the shaft deflection exceeds the misalignment compensation capacity of the bearing, typically around 2 degrees. In the 22256 CC/W33, this is mitigated by optimized internal geometry. However, proper installation and housing alignment are critical to ensure that Hertzian contact stress is distributed evenly across the roller length, preventing localized stress peaks and premature fatigue spalling.

What are the critical installation tolerances for the 22256 CC/W33?

Installation of the 22256 CC/W33 requires careful auditing of shaft and housing abutment dimensions. The da min (302 mm) and Da max (478 mm) must be strictly adhered to so the bearing is properly supported. If the housing abutment is too small, the bearing cannot manage the axial load path correctly, leading to localized stresspeaks. Proper clearance optimization during installation prevents thermal expansion from causing early bearing seizure.

How does the 22256 CC/W33 manage heavy axial loads in a vibrating screen?

The 22256 CC/W33 uses two rows of symmetrical rollers and a spherical outer raceway, allowing the load path to be distributed across a wider contact area. Even when the vibrating screen causes significant shaft deflection, the self-aligning design ensures that the load remains centered. The specific calculation factors reflect how effectively the bearing converts axial force into radial load distribution, preventing internal stress peaks that cause early failure.

Related Bearing Models

- 22252 CC/W33

- 22260 CC/W33

- 22256 CA/W33

- 22256 CC

- 22356 CC/W33

Technical Support & Global Inquiry

ZQM Bearings supports long-term supply programs for international OEMs and distributors, emphasizing batch-to-batch dimensional consistency and controlled manufacturing processes. Our engineering team ensures standardized export packaging and anti-rust surface treatment for overseas shipment, maintaining quality control across repeated production batches.

ZQM engineers provide 24/7 technical selection support to ensure the chosen solution matches your specific load and speed requirements. Request a customized quote for bulk orders or project-specific bearing requirements. Our B2B industrial procurement support is focused on operational continuity and long-term asset reliability.